Products and Services

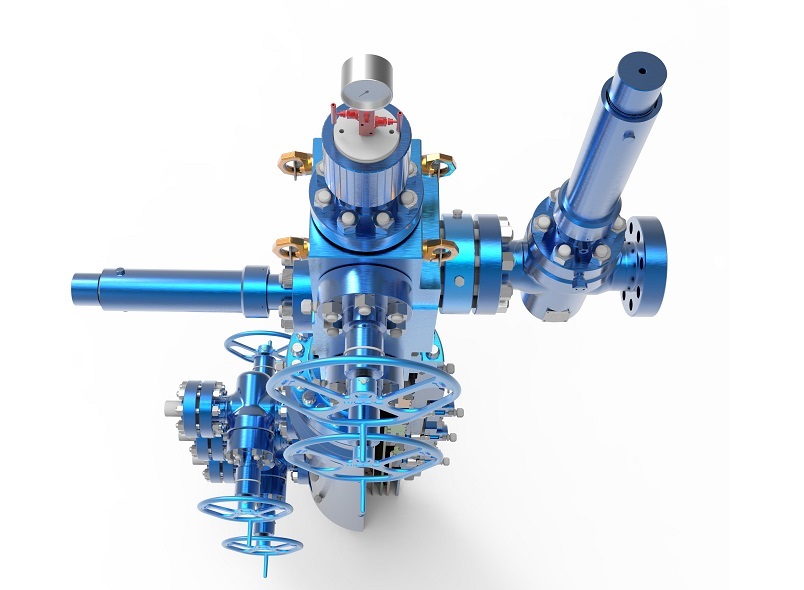

Modular Wellhead

Our range of products, WEFIC® (We Enhance Flow In Control), will offer customers quality as well as cost efficiency. Being the Centre of Excellence for Wellhead, Christmas Tree and other various Well Control Equipment…

MODULAR WELLHEAD™ SYSTEMS (MW-I)

The Modular Wellhead™ System (MW-I) is a multi-stage system that caters for different casing programs and working pressure. With option of being two or three stages, MW-I comes in nominal sizes ranging from 10" to 18-3/4" and working pressure from 3,000 psi to 15,000 psi.

The Modular Wellhead™ System is easy to operate, safe and efficient. It is designed to conform to API6A and can be used both onshore and offshore, even under severe operating condition.

Reduced Rig Time

- High speed connector, Clamp connector or Flange Lock connector

- The reduction of the connection in weldless diverter and blow-out preventer (BOP) can save rig time as much as 50%

Versatility

- Extremely versatile with the ability to accommodate different casing programs in a single system

- Minimal requirement for running tools, excellent hanging capacity and good adaptability with wide range of tubing programs including single, dual or tension tubing hangers

Seal Capabilities

- Elastomeric S-seals or Metal Lip Seal on Packoff are available

- Straight Bore Metal Seal on Tubing Hanger Neck

- Standard API Gasket Seal on Connection

Enhanced Safety

- Reduced number of BOP connections

- Operation with BOP or diverter

- High speed assembly, Weldless Sliplock connectors are available

- Reducing exposure to potential open hole and tardy jobs

Low Maintenance

- Reliable, field proven design

- No requirement for plastic packing or lockscrews

- Reduction of maintenance costs through continuous control lines

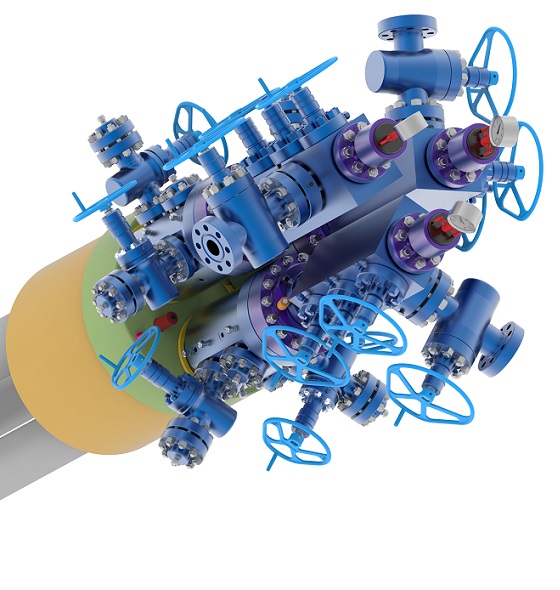

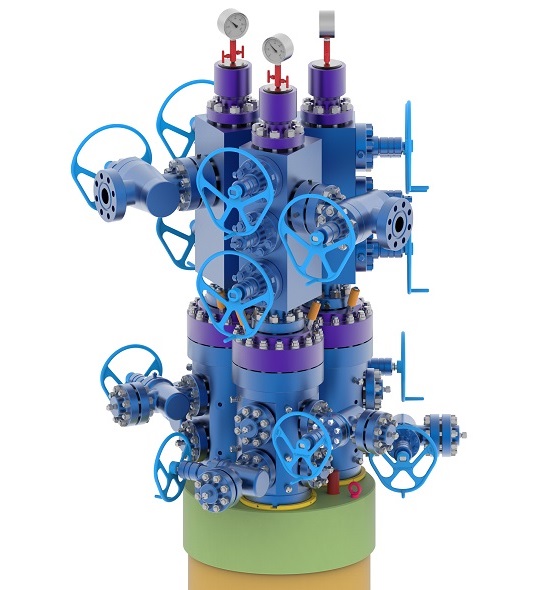

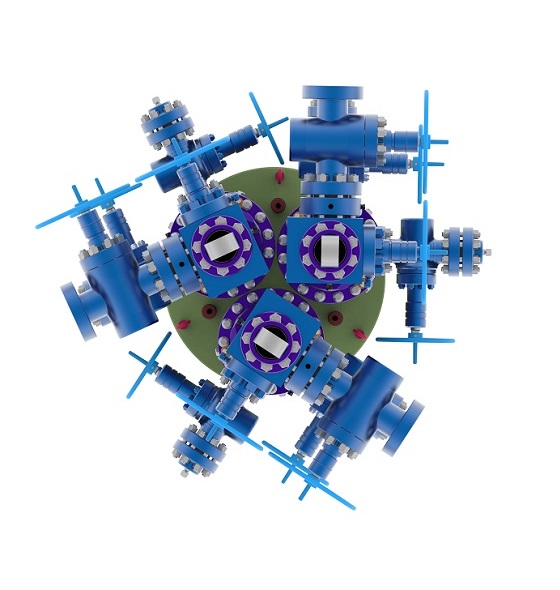

MULTIPARTITE MODULAR WELLHEAD™ SYSTEMS (MMW-I)

The Multipartite Modular Wellhead™ System (MMW-I) is designed for double or triple wellhead configuration, which can be used in the process of drilling, completion and production. MMW-I system can save up to 20% in cost of an individual well. On top of this, the system can reduce the size of the platform and increase the efficiency of producing oil.

Optimized Platform Space

- One, two or three independent wells can be drilled in the platform

- Each well can contain single or dual completion

- Modular Wellhead design does not require multi-level platform

- Smaller platform sizes and maximised use of existing platform slots

- Modular design, interchangeable components

Flexibility

- Flexibility

Reduced Rig Time

- Drilling and completion are independent between the wells

- Commitment to the second (or the third) well is not necessary after spudding

the first well - Each well can be maintained independently

- Fewer connections than spool-type wellhead

- Less connection ways than the spool-type wellhead system

- Conventional drilling and completion procedures

Enhanced Safety

- Reduced number of BOP connections

- Operation with BOP or diverter

- High speed assembly, Weldless Sliplock connectors are available

Reduced Inventory

- Identical components for each well

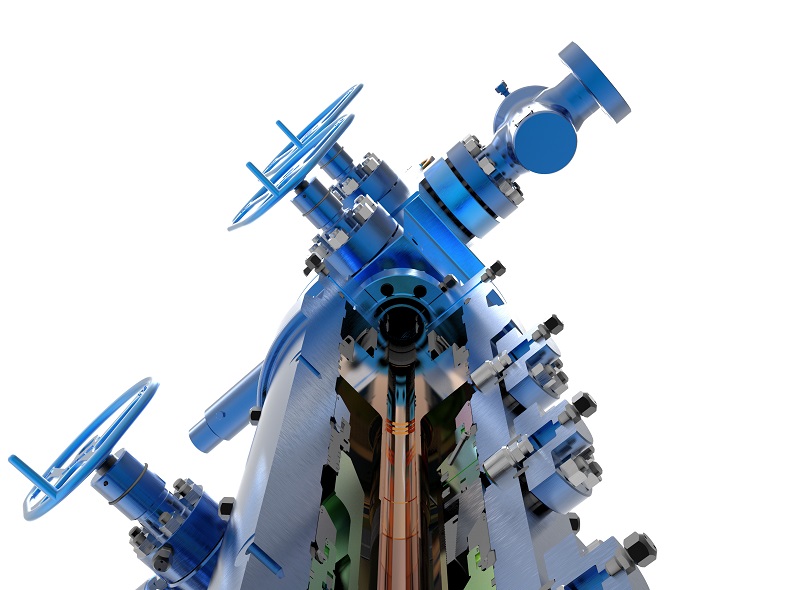

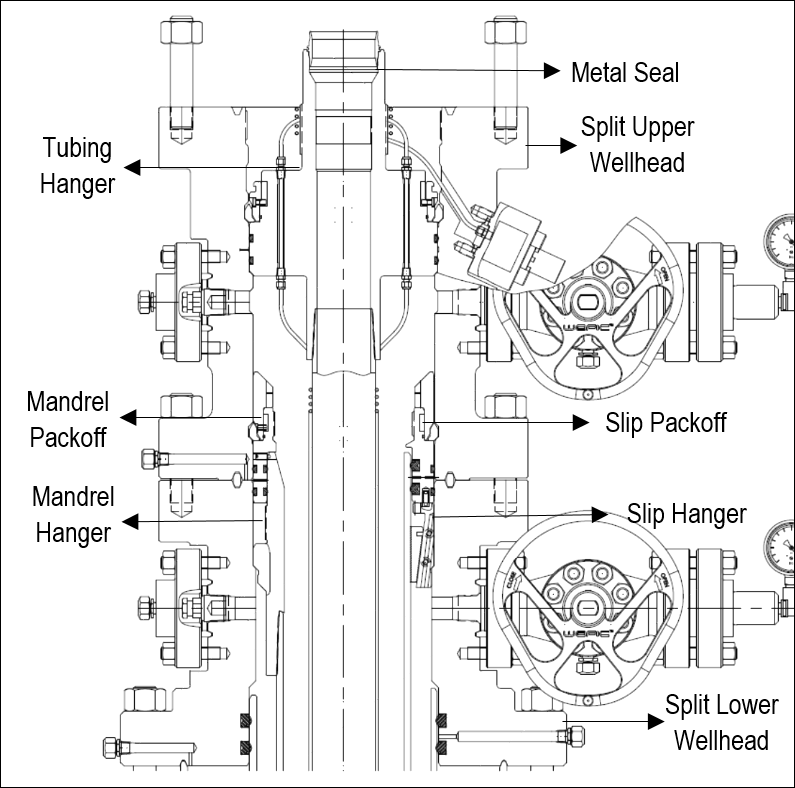

SPLIT MODULAR WELLHEAD SYSTEM (MW-I)

The Modular Wellhead (MW-I) Split System is a premium series of WEFIC® product range. Our Wellhead system is designed and manufactured to the latest edition of API 6A. We ensure all equipment goes through stringent and professional quality control and documentation to meet customer's specifications. An example below is used to explain this system.

MW-I Split System (2 Stage)

The 13-5/8" NOM MW-I split (2-Stage) system features a double load shoulder design dedicated to the landing of the 9-5/8" casing hanger and 4-1/2" tubing hanger, in the lower split MW and upper split MW wellhead respectively. The advantage of the split wellhead design, gives the option to remove upper wellhead assembly to facilitate the installation of emergency slip hanger, in the event the 9-5/8" casing becomes stuck.

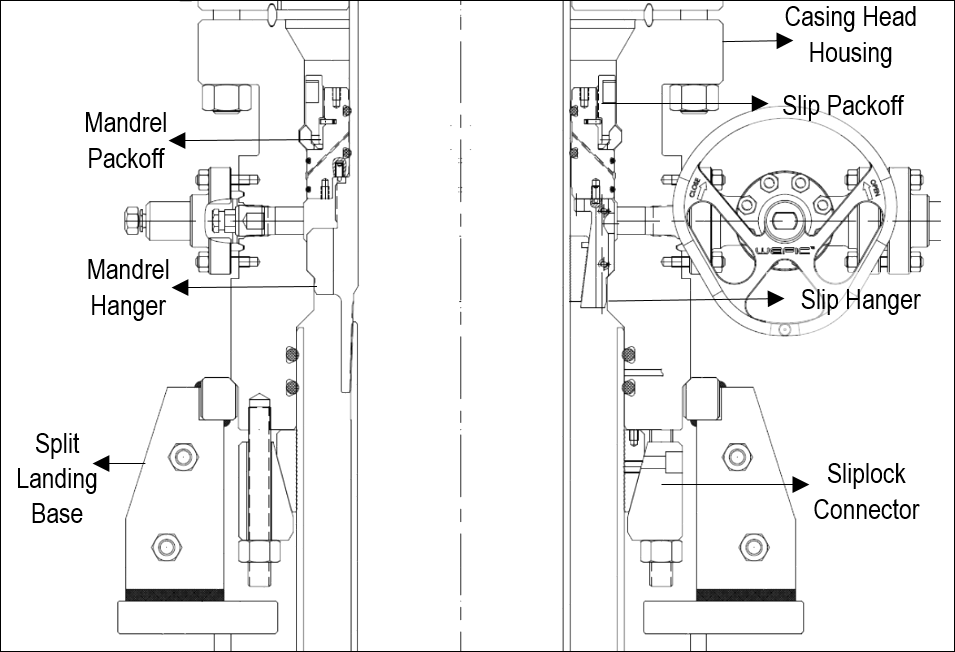

MW-I Casing Head Housing System

The Casing Head Housing proposed is type 'MW-I' 18-3/4" Nom system. It utilises the same internal lockdown concept as the split MW-I system and is designed for both mandrel and emergency slip casing hanger for 13-3/8" casing. Due to the low pressure requirement, O-rings are safety used for cost effectiveness. Bottom energised 20" casing sliplock design at the bottom of the Housing serves to fully occupy the space in the split landing base, spacing space and material cost.

Time Savings

- This single nominal size bowl design allows the split wellheads to be installed

together as a single wellhead, thus requiring only one single BOP installation.

This results in significant time saving and enhanced safety.Each well can

contain single or dual completion

Safety

- Safety is further enhanced by reduced potential leak path with the use of

internal locking mechanism instead of lockscrews.

Versatility

- With extreme versatility to meet customer requirements, the system offer

different housing bottom preps, outlet configurations, and intermediate and

top connection options. For this tender, the standard field proven API flange

connection is offered.

Ease of Operation

- Robust field proven, self-energised elastomeric seals ('S' and 'FS') are used for

the proposed system to save time and simplified the process of installation.

Double seals allow each seal to be easily tested and verified. WEFIC® straight

bore metal seal at the tubing hanger extended neck are designed to allow

direct pressure test from the annulus test port.